|  | |

| NO .: | 1 |

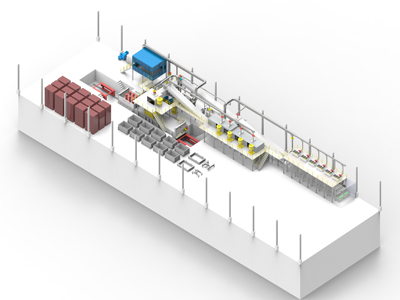

| Name: | ARTIFICIAL MARBLE PRODUCTION LINE |

|

|

|

Details:

As a professional enterprise integrating R&D, design, manufacturing, construction, installation and after-sales service of artificial stone machinery in China, WICOLI Machinery Co., Ltd. is also one of the leading companies in the research, development and production of new stone machinery processing equipment in China. On the basis of the introduction of Italian technology, the automatic marble production line has made large-scale improvement and improvement based on the experience of a large number of actual production, which makes the current production line production efficiency and quality control higher. At the same time, relying on the company's strong technical team and service strength, we provide our customers with a complete set of technical service solutions for equipment, technology, manufacturing and technology.

Production process control for each entire line produced by our company can be operated by the advanced PC. One main operator is enough to master the entire plant and production process, which is manpower-saving, but also much more efficient.The automatic material feeding, distribution, mixing, shaping, solidifying system ensures continuous and efficient production, and then the stone blocks quality are stable with less comprehensive cost.

The mature artificial stone machinery manufacturing equipment system developed by our company includes:

1) Batching system:

Adopting a new type of subtraction weighing method, the belt is over-discharged in the middle, the metering is accurate, and 10 tons of material can be weighed at one time, and the weighing efficiency is high. And with the automatic industrial computer, the technician only needs to store the formula, and then the production can be automated by simply transferring the corresponding formula according to the corresponding product. The production process is automatically recorded for easy follow-up. In addition, reasonable whole plant layout and widened belts reduce material loss during transportation and improve transportation efficiency.

2) Stirring system:

The single-color mixer adopts a double-shaft mixer, and optimizes the ratio of the width of the cylinder and the mixing diameter to shorten the mixing time and improve the uniformity of the mixing. The shaft end seal and the bearing separate structure design reduce the failure rate.

The vacuum mixer adopts the planetary reducer to provide power for the whole machine and the four large gears to synchronize, so as to ensure that the static load can be started when the multi-color fine powder board is used, so as to achieve the process requirement of stirring the color. The shaft end seal box bearing is separated and structurally designed, and the shaft end is sealed by five layers to ensure the sealing performance of the whole machine and reduce the failure rate.

3) Distribution system:

The new distribution room with high strength and large space meets the requirements of fabric technology and new product development. And ithas developed a new type of steering distribution machine, which can roll, cut, spray or dust the material under vacuum, and can produce new color products such as lightning pattern series.

The transport trolley adopts a new cylinder to lift the frame type trolley, which reduces the failure rate and reduces the waiting time of the empty mould, thereby improving the production efficiency.

4) Press system:

The new type of oscillator independently developed by our company (patent number: CN201120455638.6 and CN201120455636.7) is used for pressing, and the exciting force is larger. The same product can save 20-30kg resin and the oscillator is directly connected. Improve efficiency, reduce operating current from 200-300A to 100-180A, reducing energy consumption and failure rate. The pressing time is reduced to 8-12 minutes, which improves the production efficiency of the whole machine.

5) Environmental protection:

The dust collection is carried out by a large air bag filter, the mixer mouth and the belt corner, and the batching bucket is equipped with a dust suction port to minimize the dust in the workshop. The waste gas generated in the production process is collected and then subjected to optical microwave oxidation treatment to minimize the odor in the workshop and meet the environmental protection requirements, so as to truly produce green and environmentally friendly stones in a green and environmentally friendly manner.

6) Dual purpose equipment

The first domestic two-in-one production equipment can meet the demand for the production of artificial marble and inorganic cement stone, avoiding repeated investment by customers.

|